Model RS-98S-M

The Model RS-98S-M is a stationary rail saw table assembly that is installed to the desired height to enable cutting of rail. The saw table assembly has the ability to rotate 180-degrees equipped with a “Posi-Lock” to lock the saw head in place prior to cutting.

The saw has the following features:

- 50 HP drive at 2100 RPM (Diesel engine, electrical or hydraulic motor)

- “Posi-Lock” for quick and accurate saw head location.

- Patented oscillation rail cutting system to reduce area of abrasive wheel contact assuring a safe and efficient operation.

- Manual spark arrestors mounted around cutting head.

- Quick action abrasive wheel guard for ease of blade replacement that accepts 28” abrasive blades.

- Optional – Platform mounted to enable the addition of Rail Clamps for securing the rail to be cut.

The saw is manually operated. The saw can also be operated via a power feed system which enables the operator to remotely operate the saw to cut the rail.

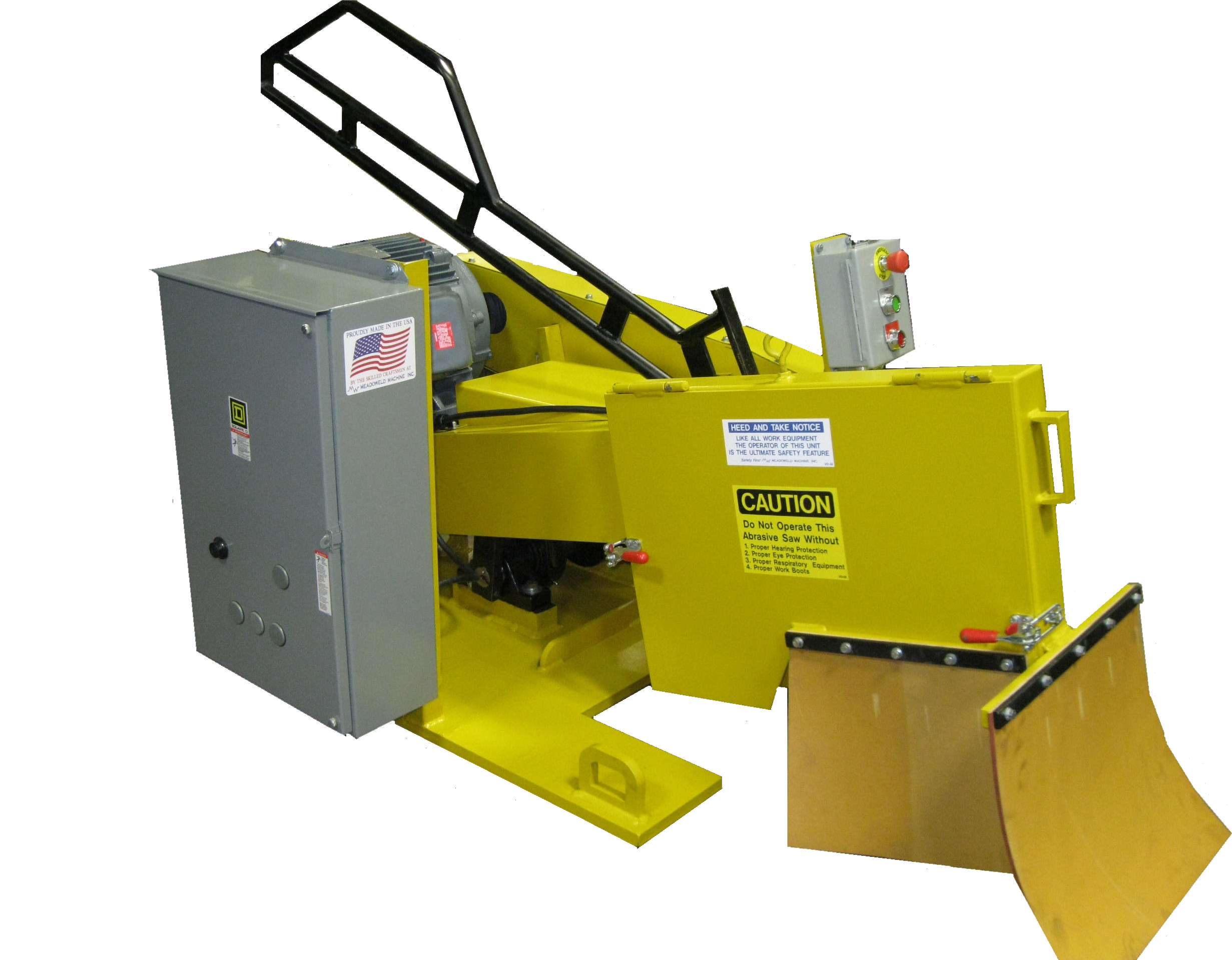

Model RS-100S-M

The Model RS-100S-M is a stationary rail saw (no axles), that is field installed to the desired height to enable cutting of rail. The saw has the following features:

- 50 HP at 2100 RPM (Diesel engine, electrical or hydraulic motor).

- Engine L.E.D.’s including hour meter.

- Heavy-duty 12 volt electric starter and 60 AMP alternator charging system.

- Heavy-duty tie down rings for ease of transport.

- Patented oscillation rail cutting system to reduce area of abrasive wheel contact assuring a safe and efficient operation.

- Manual spark arrestor (both sides) with spark deflecting belly pan.

- Quick action adjustable rail clamps designed to accommodate all rail sizes enabling operator to secure rail for cutting.

- Master switch mounted in lockable enclosure.

- Quick action abrasive wheel guard for ease of blade replacement.